"In about 120 miles of mostly highway and city driving, the suspension performed very well. I've said it before and I'll say it again - the car just soaks up all the bumps, pot holes and road cracks. It is so utterly unlike anything I have driven before.

I've had the car 15 or so years and have tried around 7 suspensions setups on this car, driven various other cars and the ride on this is just so supple while preserving the FDs awesome handling and steering feel." - Alberto: Spec Miata racer, and Fat Cat Motorsports custom FD RX-7 Elite coilover customer

A 20-year odyssey from excited fan to suspension sculptor

This is a project I've waited a very long time to do and it's only recently all the elements have come together in my understanding to deliver this ultimate suspension package that Alberto is now enjoying. In his own words, he tried at least 7 different suspension setups and finds ours 'just so supple while preserving the FDs awesome handling and steering feel... it is so utterly unlike anything I have driven before' (and yes, he also drove Ohlins DFV before!). I'm going to put a lot of detail on this project page, plus more commentary on our blog 'The Perfect Ride'. So settle in, hold on, and get ready to see and understand why our FCM Elite-tuned Bilstein monotube dampers with our proprietary Kerb Blow Off (KBO) and innovative Ripple Reducer technologies, plus damping and gas pressure optimizing techniques, are literally and figuratively the Final Answer!

Alberto first contacted me several years ago to see if we improve the suspension on his twin-turbo 1993 Mazda RX-7 (or 'FD' as the chassis is known). Connecting with him gave me flashbacks of a singular experience I had with an FD in 1996. I was at a local San Francisco region SCCA autocdross and asked for a ride-along in a new FD RX-7, piloted by Vernon Head. The sound of the motor was unlike anything I'd been in and I was amazed at the responsiveness and grip. After the run finished and I caught my breath, a single thought arose: "I want one!!"

Unfortunately, Mazda discontinued RX-7 sales in the US in the late 1990s but in 2004 introduced the Mazda RX-8. It captured a following and much respect from many journalists and car enthusiasts; Jeremy Clarkson of Top Gear fame praised the RX-8's handling dynamics and the smooth, high-revving Wankel rotary that distinguishes the R-badged Mazda cars. Prior to working on Alberto's FD, I had designed suspensions for several RX-8s and an FC RX-7 used for SCCA National Solo autocross (with no sway bars!). During product development in 2011, I co-drove a customer's STX-class RX-8 at several NW region SCCA regional and then National autocross events. With our FCM Elite suspension in place and feeling a natural connection with the car, I eeked out a win at the 2011 SCCA National Tour at Packwood, WA in the 17-driver deep STX class. That was a tremendous thrill I'll always remember and I wrote about the adventure here on Miata.net.

Just shy of two months later, I'd again co-drive that RX-8 at the Solo National Championships. Having attended in '08, '09, and '10, I'd finally win my first trophy - finishing 10th out of 43 drivers. That was the last year the early Civics were allowed in that class so it felt good to finish ahead of a few of them. I simply loved driving the RX-8! When looking for our next shop development vehicle in 2012, the RX-8 was at the top of my list, but I needed more experience working on strut-type cars so I turned to the BMW E46 chassis instead. Still, the experience of owning and racing a rotary is calling ...

Alberto first contacted me several years ago to see if we improve the suspension on his twin-turbo 1993 Mazda RX-7 (or 'FD' as the chassis is known). Connecting with him gave me flashbacks of a singular experience I had with an FD in 1996. I was at a local San Francisco region SCCA autocdross and asked for a ride-along in a new FD RX-7, piloted by Vernon Head. The sound of the motor was unlike anything I'd been in and I was amazed at the responsiveness and grip. After the run finished and I caught my breath, a single thought arose: "I want one!!"

Unfortunately, Mazda discontinued RX-7 sales in the US in the late 1990s but in 2004 introduced the Mazda RX-8. It captured a following and much respect from many journalists and car enthusiasts; Jeremy Clarkson of Top Gear fame praised the RX-8's handling dynamics and the smooth, high-revving Wankel rotary that distinguishes the R-badged Mazda cars. Prior to working on Alberto's FD, I had designed suspensions for several RX-8s and an FC RX-7 used for SCCA National Solo autocross (with no sway bars!). During product development in 2011, I co-drove a customer's STX-class RX-8 at several NW region SCCA regional and then National autocross events. With our FCM Elite suspension in place and feeling a natural connection with the car, I eeked out a win at the 2011 SCCA National Tour at Packwood, WA in the 17-driver deep STX class. That was a tremendous thrill I'll always remember and I wrote about the adventure here on Miata.net.

Just shy of two months later, I'd again co-drive that RX-8 at the Solo National Championships. Having attended in '08, '09, and '10, I'd finally win my first trophy - finishing 10th out of 43 drivers. That was the last year the early Civics were allowed in that class so it felt good to finish ahead of a few of them. I simply loved driving the RX-8! When looking for our next shop development vehicle in 2012, the RX-8 was at the top of my list, but I needed more experience working on strut-type cars so I turned to the BMW E46 chassis instead. Still, the experience of owning and racing a rotary is calling ...

Applying KBO, our most important technological advance, to re-engineer what a damper can do (and without needing knobs!)

Once Alberto was ready to proceed on improving his iconic FD's suspension, the timing also right for us. I've continually improved our methods which have led me to focus less on requiring adjustable damping for high-performance suspensions (much more on that soon!) and more on altering the fundamental physics of the damper's behavior. In this way, the correct adjustments are made through our detailed and customer-specific FCM Elite build process before the user even receives their Elite suspension. For example, from having used double-adjustable dampers on Senna during track and autocross testing, our integrated data acquisition helped determine that we actually needed to reduce high speed compression damping to further improve grip, while we also needed more low speed compression to keep the suspension from jacking down. This would require a change to how the damper created force and we couldn't achieve that with the standard digressive piston and shim behavior. Something new was needed and my mind was turning.

Developed through fall and winter 2013, following a very restorative sabbatical in Europe, I introduced our KBO (Kerb Blow-Off) technology in early 2014. KBO is a highly-responsive, spring-loaded blow-off mechanism which expresses the state of the art in functional damper design for greatest reliability and performance. Our Kerb Blow-Off technology softens the upward impact of sharp road features by greatly reducing the damper's high speed compression force 'slope'. Slope refers to the rate of change of force as you cycle the damper at higher shock speeds (see graph below). The rebound forces / slopes is also very important to consider, but the magic of KBO lets us use MORE compression force to 'lifting' and 'support' the chassis, so we actually end up SOFTENING rebound force! We're able to get better control through the increased low speed compression force without having to resort to too much low speed rebound force which is what nearly every shock manufacturer and OE supplier does.

When you watch the 'Introduction to KBO' video, you can hover over parts of the Youtube screen and see explanations for each segment of the compression curve; what that car is doing in that speed region and why KBO is a benefit there. Through KBO's crucial ability to de-couple low speed compression force from high speed compression force, KBO allows us to use MORE low and mid-speed compression damping (to provide chassis support during initial compression events which reduces the chance of bottoming out) with LESS high-speed compression damping (taht would cause uncomfortable upward 'launching' as too much force builds up). A picture's worth a thousand words, so here's a snapshot of the end screen of the video but the short 2 min clip is worth watching to see how fundamentally innovative and important KBO is!

Developed through fall and winter 2013, following a very restorative sabbatical in Europe, I introduced our KBO (Kerb Blow-Off) technology in early 2014. KBO is a highly-responsive, spring-loaded blow-off mechanism which expresses the state of the art in functional damper design for greatest reliability and performance. Our Kerb Blow-Off technology softens the upward impact of sharp road features by greatly reducing the damper's high speed compression force 'slope'. Slope refers to the rate of change of force as you cycle the damper at higher shock speeds (see graph below). The rebound forces / slopes is also very important to consider, but the magic of KBO lets us use MORE compression force to 'lifting' and 'support' the chassis, so we actually end up SOFTENING rebound force! We're able to get better control through the increased low speed compression force without having to resort to too much low speed rebound force which is what nearly every shock manufacturer and OE supplier does.

When you watch the 'Introduction to KBO' video, you can hover over parts of the Youtube screen and see explanations for each segment of the compression curve; what that car is doing in that speed region and why KBO is a benefit there. Through KBO's crucial ability to de-couple low speed compression force from high speed compression force, KBO allows us to use MORE low and mid-speed compression damping (to provide chassis support during initial compression events which reduces the chance of bottoming out) with LESS high-speed compression damping (taht would cause uncomfortable upward 'launching' as too much force builds up). A picture's worth a thousand words, so here's a snapshot of the end screen of the video but the short 2 min clip is worth watching to see how fundamentally innovative and important KBO is!

Everything summarized in one image: An FCM Kerb Blow-Off (red curve) damper vs. a standard digressive compression curve (blue curve). KBO allows us to increase low speed compression for better control, increase mid speed compression to reduce suspension bottoming out, while also decreasing high speed compression to improve absorption of sharp road features. How can it possibly get any better than this?!

Click here for a short video I made from a voicemail our turbo Miata KBO Elite customer Jeff left after winning his first autocross with our KBO Elite dampers!

He kept the same spring rates, sway bars, bump stops, and ride heights - only changing from the previous digressive dampers to the new dampers with KBO technology.

Since using Senna for the first track test of KBO at Thunderhill in early 2014, I've been continually making refinements to our novel KBO technology, in terms of material choice, tolerances, and complementary / patent pending innovations. I was starting to feel our KBO superior to anything else available (including Ohlins DFV technology) plus integrated more easily and at much lower cost than Penske's regressive valve. In fact, we have our own regressive damping setup already prototyped but that's a topic for another Project. For those who may be skeptical at my claims of superiority, numbers talk: watch this video refering to work we did on a BMW E46 M3, where even our standard digressive valving provides LOWER high speed compression (and better comfort on sharp bumps!) than the Ohlins DFV! There are other deficiencies of the Ohlins setups I've seen, predominantly related to not incorporating their own 'high-frequency piston' technology for road/track use and using more high speed rebound damping than is necessary or beneficial for grip or control. Spring rate choice is also an issue with many / most aftermarket setups I look at and there's no over-riding guidance at most companies to educate customers about why their spring rates really do matter. Educate yourself as to the benefits of Flat Ride tuning in my first introductory video 'What is Flat Ride and why should you care?', and this follow-up video 'Why Flat Ride matters - A fascinating road test with NO damping!' which was a great real-world example of how little damping you need when the spring rates are working in favor of 'Fast Settling' which is an important synonym of 'Flat Ride.' Flat Ride doesn't just apply to comfy passenger cars! It's not just about ride quality, people - Flat Ride is about handling and responsiveness!

KBO is absolutely a game-changer in terms of reducing road harshness, increasing grip, and improving vehicle responsiveness. It truly opens up the possibility of creating a suspension with essentially NO compromise and that is what Alberto is experienced and describing in his feedback. Many FCM Elite customers have felt those benefits for nearly 3 years now. It's a win-win-win for more grip, increased ride comfort, and added responsiveness!

Alberto's build would also receive our Ripple Reducer option, inspired (somewhat ironically) by the Ohlins high-frequency piston reserved for off-road application. I'd been able to apply the concept to on-road and competition setups where we found better ride quality AND increased cornering grip. Multiple reviews, including this from Miata owner Tom 'Apexanimal' demonstrate how amazingly effective Ripple Reducer is, even without KBO. In modifying the hydraulic piston to introduce multiple small holes instead of using bleed shims, we achieve two benefits:

First, reduced friction through providing a vertical, straight-thru fluid path for fluid instead of forcing fluid through multiple bends (the piston ports and shims discs) which increases

Second, ability to run a much lower nitrogen charge pressure which translates into a lower static gas force on the shock shaft. Because there is less gas force

Third, for damper movements that are small displacement and high frequency (described as 'road patter' or 'road roughness'), the damper is able to track those 'noisy' motions without needing to generate excessive force as with a non-drilled piston which relies solely on shims or cartridges. Even the most sophisticated magneto-rheologic or semi-active magnetic induction switched production dampers are limited in their high frequency response. We have proven to ourselves and through our customers that the positive benefit of introducing precisely-sized holes on the damper piston has only benefits to improved grip and better ride quality. Why wouldn't every manufacturer use this then? It takes optimization to a specific application which is not as easy a production process. Second, it requires additional secondary machining steps as you can't cast these holes and get precise results. This operation would add more cost and manufacturers are currently more concerned with cost than with optimizing ride quality for their customers. With the advent of CNC machines and advanced mold-making processes, I believe Ripple Reducer appearing in production is only a matter of time, especially as we report on which companies are leading the race when it comes to the best ride and handling balance.

Want to know a secret? What I'm really doing is building more and more refined 'rally suspensions' for road and track use. Even Formula 1 cars are designed to promote grip via softer low speed rebound and firmer low speed compression. You want more 'area under the compression curve' in low and medium speeds to provide supporting force to the suspension at low and mid shock speed. With that added compression we can soften the low and mid speed rebound damping which lets the tires extend down to and stay in touch with the ground more of the time. This superior balancing of rebound and compression forces, to prevent 'jacking down' and promote 'lifting up', improves tire adhesion (aka grip) and smooths out the ride. Fast rally car suspensions are a pleasure to drive on the street - and wicked fast!

Reposted from the F1technical.net

===

DaveW

hardingfv32 wrote:

Definition of rebound/compression biased shock (damper) solution, please.

This plot shows the rear damper force/velocity trajectories. The sign convention is positive compression. That shown in red is rebound biased, whilst that shown green is (slightly) compression biased.

The corresponding damper position time histories are shown here. Again, positive displacement is compression. Hopefully, you can see that the rebound biased damper used a maximum compression deflection of 16mm. with this input, whilst the compression biased damper used a maximum of just over 6mm.

===

This means the

Since using Senna for the first track test of KBO at Thunderhill in early 2014, I've been continually making refinements to our novel KBO technology, in terms of material choice, tolerances, and complementary / patent pending innovations. I was starting to feel our KBO superior to anything else available (including Ohlins DFV technology) plus integrated more easily and at much lower cost than Penske's regressive valve. In fact, we have our own regressive damping setup already prototyped but that's a topic for another Project. For those who may be skeptical at my claims of superiority, numbers talk: watch this video refering to work we did on a BMW E46 M3, where even our standard digressive valving provides LOWER high speed compression (and better comfort on sharp bumps!) than the Ohlins DFV! There are other deficiencies of the Ohlins setups I've seen, predominantly related to not incorporating their own 'high-frequency piston' technology for road/track use and using more high speed rebound damping than is necessary or beneficial for grip or control. Spring rate choice is also an issue with many / most aftermarket setups I look at and there's no over-riding guidance at most companies to educate customers about why their spring rates really do matter. Educate yourself as to the benefits of Flat Ride tuning in my first introductory video 'What is Flat Ride and why should you care?', and this follow-up video 'Why Flat Ride matters - A fascinating road test with NO damping!' which was a great real-world example of how little damping you need when the spring rates are working in favor of 'Fast Settling' which is an important synonym of 'Flat Ride.' Flat Ride doesn't just apply to comfy passenger cars! It's not just about ride quality, people - Flat Ride is about handling and responsiveness!

KBO is absolutely a game-changer in terms of reducing road harshness, increasing grip, and improving vehicle responsiveness. It truly opens up the possibility of creating a suspension with essentially NO compromise and that is what Alberto is experienced and describing in his feedback. Many FCM Elite customers have felt those benefits for nearly 3 years now. It's a win-win-win for more grip, increased ride comfort, and added responsiveness!

Alberto's build would also receive our Ripple Reducer option, inspired (somewhat ironically) by the Ohlins high-frequency piston reserved for off-road application. I'd been able to apply the concept to on-road and competition setups where we found better ride quality AND increased cornering grip. Multiple reviews, including this from Miata owner Tom 'Apexanimal' demonstrate how amazingly effective Ripple Reducer is, even without KBO. In modifying the hydraulic piston to introduce multiple small holes instead of using bleed shims, we achieve two benefits:

First, reduced friction through providing a vertical, straight-thru fluid path for fluid instead of forcing fluid through multiple bends (the piston ports and shims discs) which increases

Second, ability to run a much lower nitrogen charge pressure which translates into a lower static gas force on the shock shaft. Because there is less gas force

Third, for damper movements that are small displacement and high frequency (described as 'road patter' or 'road roughness'), the damper is able to track those 'noisy' motions without needing to generate excessive force as with a non-drilled piston which relies solely on shims or cartridges. Even the most sophisticated magneto-rheologic or semi-active magnetic induction switched production dampers are limited in their high frequency response. We have proven to ourselves and through our customers that the positive benefit of introducing precisely-sized holes on the damper piston has only benefits to improved grip and better ride quality. Why wouldn't every manufacturer use this then? It takes optimization to a specific application which is not as easy a production process. Second, it requires additional secondary machining steps as you can't cast these holes and get precise results. This operation would add more cost and manufacturers are currently more concerned with cost than with optimizing ride quality for their customers. With the advent of CNC machines and advanced mold-making processes, I believe Ripple Reducer appearing in production is only a matter of time, especially as we report on which companies are leading the race when it comes to the best ride and handling balance.

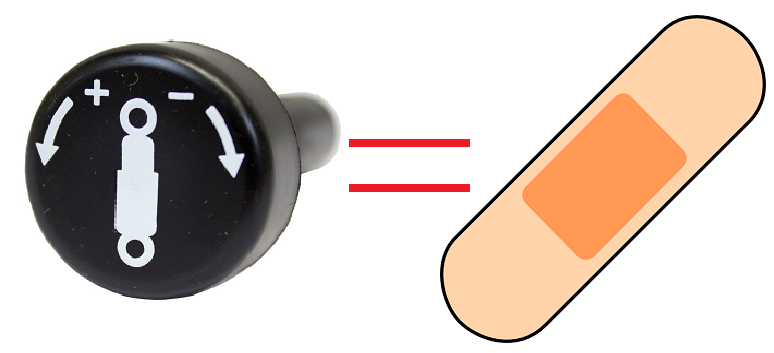

Here's an inconvenient Suspension Truth - if you're 'Playing with Knobs', you're almost certainly putting band-aids on a bad design!

(Or click here for an adult version)

Just to remind you of a fact - Alberto's shocks have no knob. He can't change the damping, nor would he need to. We've looked at the whole damping range he'd need his suspension to cover and every aspect has been carefully tuned with the right equipment and understanding so he just turns the key and drives. It's a common (though erroneous) expectation that a 'good quality shock should have a knob' so the user can change the settings to what I want, for different surfaces and conditions, blah blah blah.' On the surface, this seems to make sense but in practice (mine and many customers who are very serious about their racing results) you get better results focusing on tire pressures, ride height, sway bar, and alignment settings than screwing around with damping. Yes, I know what you're thinking -

I knew his FCM Elite-equipped FD RX-7 would be a flagship vehicle we could proudly showcase, since he wanted our best technology and did not want one, two, or more knobs to tweak here and there. He'd come for a ride in our FCM Elite-tuned BMW 330i sedan with KBO and Ripple Reducer and was very impressed - "I want my RX-7 to feel like that." You got it!

So why the 'cult of adjustability?' Indeed, nearly all aftermarket shock suppliers have programmed customers to OBEY that standard idea that knobs are necessary and beneficial. Of course, those same designers don't tell you about things like rebound-to-bump ratio, gas charge pressure (& effective shaft gas force), jacking down, etc. But go ahead, trust us - we know better than you poor silly consumers! I know the story, 'cause I used to be one of those enthusiasts. Proud of the Koni Sports on my Neon, then my Miata; constantly running for the adjuster after each autocross run, and especially to soften then after the race event so I could drive home with LESS discomfort. Funny, I never found a setting that worked quite right for that ride home. I had to begin exploring the magic of a quality monotube (Bilstein) and the build quality and consistency, plus understand what off-road and rally suspension tuning could teach me before seeing the lies of 'rebound is your friend!'

Converting from being a "knob-goblin" to accepting an un-holey-damper was actually a liberating experience! As I coudl see and feel what created grip, and how grip and comfort were intimately related, I started experiencing the full potential of a well-balanced suspension. The first time I experienced a suspension that DIDN'T jack down (meaning, the rebound damping was NOT higher thant he compression damping, at any shock velocity!) was a total relevation. I felt like I'd been given cheat codes to the game of Life. My car could corner, handle bumps, and grip better than ever before. People I'd give test rides were amazed, and still are. I loved giving those test drives to show off what a 'supportive' suspension could do, instead of suffering with 'abusive' relationships with poorly-tuned shocks. It was ignorance of the 'physics of suspensions', beyond marketing, hype, and misinformation, that had kept me in the dark but I was stepping into the light and bringing my customers with me.

With further testing, modeling of settings, damping ratio calculations, and careful attention to driving dynamics I've become convinced that NO KNOBS is the right solution for 99% of Elite customers and situations. Knobs are unnecessary and create just another potential failure point (as anyone who's been around the block has seen with many adjustable shocks leaking from their adjusters!). Well, what are those driving dynamics to consider? The interplay between driver inputs / road disturbances / chassis response; a solid real-world understanding of how to select spring rates and sway bars (not just 'stiffer is better!') plus how those factors tie in to the shock absorber (or damper) tuning.

Over the years, from extensive data acquisition efforts on my own, I've designed and refined our FCM Elite build process so we're able to build optimal settings into each FCM Elite damper set. Those Elite customers who actually NEED knobs are 1% of our users and are nearly exlusively competitive racers who have the necessary experience (and usually data acquisition (DAQ) tools) to really benefit from that adjustments. Most crucially, we design adjusters that provide some fine-tuning BUT with a fundamentally sound and well-chosen baseline damping curve. Even more ironically, I've heard from multiple customers of ours with single- or double-adjustments that their final settings were very close or identical to what I recommended from the factory. And those settings were the same as someone who got a knob-less setup would have had. "I wish I'd just trusted you and left the knob out!" is something I've heard many times.

But the desire to tweak is very powerful - we are curious creatures after all! So this tendency to tweak PLUS an expectation that the knob gives you some secret power combine to create an important and subversive psychological effect! I would actually call it a psychological crutch, because having the knobs is satisfying to your ego, but you also end up thinking that the knob is going to help you 'dial in' the shock to where you really need the car to be (whatever that means!). How do you know that's true? You really don't, in point of fact. A generic off-the-shelf shock is designed for some typical setup, but you have NO IDEA if the damping provided was determined through an intelligent, careful design process, or was just copied from some OE design curve (what often happens), or was designed to intentionally give someone the 'sensation of performance' while not actually allowing the tires to work at their 100% best.

So instead of choosing a highly-optimized suspension (such as we produce and provide evidence for) and learning to extract all the capability from it, making you a better driver, someone who 'just really needs a knob' might go somewhere else and be smug in their belief that their non-optimized suspension is better. It's not, my poor misinformed friend, as Alberto has demonstrated through his years of testing and evaluation before coming to an FCM Elite solution. But keep reading and you'll visually see why our solutions are better than anything else - period.

You have two chocies: tell your ego to chill out, let go of the knob, and savor the supple control and capability of a fantastically optimized suspension. Or go get that baby bottle, a blankie, a pacifier, that wee little knob. "Here little one, chew on this - ah yes, it'll make you feel better! Whoops, gotta change your diaper now!" Your butt won't be able to tell you what setting is actually giving the best grip. Mine certainly didn't, except when I realized the fastest setups were also the smoothest and best riding. The tires need to stay in contact with the ground at all times, and recover from disturbances quickly and smoothly. I've hit berms at high speed with shocks half the rebound of what they came with from Bilstein. I know I'm a good driver, but it's not just the driving ability - it's the confidence, the calmness, the ease behind the wheel that makes me and my vehicle one integrated unit. I dare say, if I was still a knob-boy, I wouldn't appreciate what a relief it is to know, from feedback in my body and calculations with my mind, how . Would you feel this intuitively confident doing a mid-corner slalom at 70mph to avoid a squirrel? I never did when I was dealing with too much rebound in those 'other' shocks I owned and tested!

The typical knobs on your typical aftermarket shock is a tool for confusing the mind and frustrating the body. They NEVER get the setting you need - NEVER! I've seen this fact on every single damper I've every looked at, no exceptions. Yet because you DO have a knob, and you think the designers are smarter than you and know what you need even though you probably have no idea what the knob is doing, you trust that just playing with the knob will get you to the right setting to make everything better. And worst of all, when you can't find that ideal setting you usually think something is wrong with YOU - and you doubt yourself instead of pointing the finger back at Koni, or Ohlins, or AST, or KW, or anyone you're getting the knob from and asking 'why can't I ever find a setting that isn't harsh?' To see what I mean visually, watch the Playing With Knobs videos (from about 10:00 to 13:00 is the part I'm referring to here).

Remember, I had to learn for myself what a shockingly powerful psychological crutch the knob is. I learned through testing many different shocks, doing damping calculations, and then running those dampers on my cars. I do recommend any 'knob-boys' watch the entire 'Playing with Knobs' video; you may not like to hear what I'm saying, but it's still true. I give more proof below.

Assessing the factory suspension - benefits of FCM Elite consulting

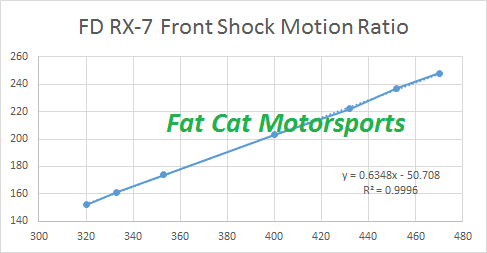

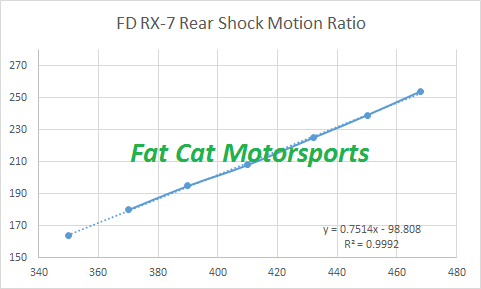

Okay, back to specifics on his build! Alberto had searched a while to find the right FD for him, one which hadn't been severely modified or abused. He's taken great care of it since; no surprise - it's a consummate, iconic, collectable sports car unlikely to ever see production again. Alberto upper the power a bit, but not wildly-so. The car already had an Eibach front bar from the previous owner and I guessed (but wasn't sure until later) that we could retain that along with the factory rear bar once all is said and done. I needed more information than he could provide (motion ratios, position where bump stop contacts damper body, etc.) so after my recommendation, he purchased several hour's consulting time so I could make the various necessary measurements. These included spring / damper / sway bar motion ratios, wheel travel measurement at full droop / static height / bump stop contact / full bump, factory bump stop lengths and spring rates, and what primary spring rates plus bump stops would be needed to produce the kind of ride / handling balance he wanted. The consulting time he paid for is an essential step in to characterizing a new platform and this is why we call our owners Elite because they understand the value of investing in Quality, both for information and upgrades.

From the rate of the Tein lowering springs he'd been using, along with taking the factory rubber bump stop spring rates, I could determine the true 'ride' spring rate was much higher than expected. I found from my wheel travel measurements that the FD RX-7 bump stops engaged early and often, especially up front. The bump stops contribute about 200 to 250 lb/ft rate which significantly amplified the ride rate. This main spring+firm bump stop was a similar recipe to what Mazda had been doing on the first gen (NA) 1990-1997 Miata in production before and simultaneous to the FD RX-7. It wasn't until the NB Miata (1999) that the modern micro-cellular polyurethane (MCU) bump stop was standard on Mazda's fleet. So the FD RX-7, while having a powerful and smooth engine output, lacked the chassis sophistication on rougher or broken roads. We'd be doing something about that!

Alberto's review first, then my commentary

Go here for the the full thread on rx7club.com for his FCM Elite KBO (Kerb Blow-Off) Ripple Reducer suspension build. I've highlighted his essential comments below:

With work, the house and racing, I have only put 10 miles on these so don't have any real feedback on ride. I have noticed just driving around my 'hood on supermarket runs that the car rides compliantly and that Bots dots are absorbed much better than anything else I've been in. I'm looking forward to spending some quality time in the FD in the coming months driving and cutting up the back roads and will report back on impressions further...

Small update (end of September)

I've been busy trying to run the last couple of Spec Miata races and helping a friend with his SM build so haven't had much time to pleasure drive the FD. I did take it out last weekend to a dog show and put 60 miles on it. I was seriously impressed with the ride quality! It was frickin' amazing! I intentionally hit rough road patches that I would normally steer around to test the suspension out and it was stunningly smooth! All the road imperfections just gets soaked up!

As a side benefit, the interior is much, much quieter w/o the shock from road vibrations vibrating the plastic bits in the interior.

(Update early November)

I'm stunned by how nice the suspension felt. I need to get some more time behind the wheel and really feel this out. So far, I'm very very impressed with the shocks.

(Update late November)

Back to critiquing ride quality.

I did have a boring-ish 120 mile drive in the car last weekend. Mostly highway and city driving through Berkeley. The suspension performed very well. I've said it before and I'll say it again - the car just soaks up all the bumps, pot holes and road cracks. It is so utterly unlike anything I have driven before.

I've had the car 15 or so years and have tried around 7 suspensions setups on this car, driven various other cars and the ride on this is just so supple while preserving the FDs awesome handling and steering feel.

Good times.

Alberto's Mazda RX-7 FCM Elite front coilover about to be installed

Alberto's Mazda RX-7 FCM Elite rear coilover about to be installed

(Update the following May)

Just finished the first day on track with these plus 175 miles of street driving getting up here.

Long story short, I'm happier than ever with my choice. Car is a **** load of fun on track.

Day two tomorrow!

A few thoughts on the crucial importance of rebound-to-bump ratio and trumping Ohlins

It was clear from the Koni Sport and Bilstein dynos that extreme amounts of 'control' were being designed into the suspension and the dampers. It was basically to 'lock' the car down into the bump stops at any appreciable speed or any undulations or bumps in the road. There was no provision to allow for the relaxation of the suspension to prepare for a subsequent bump. This kind of 'single event' design will really only ever be somewhat-acceptable on very smooth roads or race tracks. It's not commonly used with US or European manufacturers but I have seen it with newer Japanese tuners. I think there's a very unfortunate side-effect that people 'except' a good suspension to have that really aggressive 'jacking down / harsh' feel and call it normal. Then something softer comes along, like what we do, and they aren't sure what to make of it. The car is faster and smoother - how is that possible?

Well, even before getting into KBO, I FINALLY realized a couple years ago that the nitrogen charge pressure, the rebound force, and the compression force were connected. The gas pressure, which on a monotube usually is fairly high from the factory, reduces the effective rebound force and increases the effective compression force. The gas pressure creates a 'gas spring' whose preload must be overcome as you attempt to move the damper into the shock body. When the shock is extending, the force required to extend it is REDUCED by the amount of the gas force. This is a uniform offset, across the range of velocities.

Even with manufacturers like Ohlins, when it comes to their 'track-focused' DFV (dual flow valve) setup, there is too much high speed rebound damping present - more than the vehicle really needs for control and stability. Users will convince themselves they need this much damping but what's actually happening is the setup has given say 80% of total capability from the tires and chassis, but has neutered the remaining capability. Why does this happen? It may not be intentional, but the result is the same - rougher ride that makes you feel you're going fast but is actually not as high-grip, smooth, or effortless to drive as a softer damped setup. Where do the problem occur? First, through ignoring or not optimizing the relationship between front and rear suspension frequencies, also known as tuning for Flat Ride. Second, through not considering and optimizing the microscopic adhesion of the tire via lower nitrogen gas pressure inside the damper and not utlizing a high-frequency modification like Ripple Reducer which I've discovered allows even LESS gas pressure to be used without introducing any hysteresis! Third, by not realizing that excess rebound causes 'jacking down' which is detrimental to cornering grip & stability, ride quality, and the driver's psychological confidence in extracting every ounce of grip from the tires. This jacking down may not be apparent until you're going fast enough to excite the damper at mid and high speed. The engineering term for this is 'decreasing dynamic set point.' It's like walking down a road and your legs are getting chopped out from under you until you're just bouncing on your torso. A suspension that's jacking down is essentially being canabalized and it's ONLY the dampers that cause jacking down. It's really ONLY the dampers that cause ride discomfort and reduction of grip. While some specific racing situations (on GROOMED smooth surfaces!) can warrant a rebound-heavy, jacking down setup, no rally car or road going car worth speaking highly about jacks down. This is also why there is so much 'average' tuning for many vehicle and why our Smooth Ride Campaign will help illustrate, through our simple and easy to use mobile app, whether or not your vehicle is delivering acceptable ride quality. You will be able to visually see the impact of too much rebound. I can guarantee that any FCM Elite setup since 2014 would ride better than any Ohlins DFV, and out-grip them as well. Since we're on the subject of Alberto's FD RX-7, I know with confidence he'll trounce anyone using Ohlins, in any objective test. I'm happy to be part of that evaluation. I've displayed the fruits of my work on his dampers here, with the confidence that even if someone went and duplicated the rebound curve, you wouldn't get Ripple Reducer without the effort to size and drill those holes in the piston. And you wouldn't have KBO which is another essential ingredient in making our FCM Elite dampers the most technologically sophisticated and street-or-track-capable monotubes in the world.

Well, even before getting into KBO, I FINALLY realized a couple years ago that the nitrogen charge pressure, the rebound force, and the compression force were connected. The gas pressure, which on a monotube usually is fairly high from the factory, reduces the effective rebound force and increases the effective compression force. The gas pressure creates a 'gas spring' whose preload must be overcome as you attempt to move the damper into the shock body. When the shock is extending, the force required to extend it is REDUCED by the amount of the gas force. This is a uniform offset, across the range of velocities.

Even with manufacturers like Ohlins, when it comes to their 'track-focused' DFV (dual flow valve) setup, there is too much high speed rebound damping present - more than the vehicle really needs for control and stability. Users will convince themselves they need this much damping but what's actually happening is the setup has given say 80% of total capability from the tires and chassis, but has neutered the remaining capability. Why does this happen? It may not be intentional, but the result is the same - rougher ride that makes you feel you're going fast but is actually not as high-grip, smooth, or effortless to drive as a softer damped setup. Where do the problem occur? First, through ignoring or not optimizing the relationship between front and rear suspension frequencies, also known as tuning for Flat Ride. Second, through not considering and optimizing the microscopic adhesion of the tire via lower nitrogen gas pressure inside the damper and not utlizing a high-frequency modification like Ripple Reducer which I've discovered allows even LESS gas pressure to be used without introducing any hysteresis! Third, by not realizing that excess rebound causes 'jacking down' which is detrimental to cornering grip & stability, ride quality, and the driver's psychological confidence in extracting every ounce of grip from the tires. This jacking down may not be apparent until you're going fast enough to excite the damper at mid and high speed. The engineering term for this is 'decreasing dynamic set point.' It's like walking down a road and your legs are getting chopped out from under you until you're just bouncing on your torso. A suspension that's jacking down is essentially being canabalized and it's ONLY the dampers that cause jacking down. It's really ONLY the dampers that cause ride discomfort and reduction of grip. While some specific racing situations (on GROOMED smooth surfaces!) can warrant a rebound-heavy, jacking down setup, no rally car or road going car worth speaking highly about jacks down. This is also why there is so much 'average' tuning for many vehicle and why our Smooth Ride Campaign will help illustrate, through our simple and easy to use mobile app, whether or not your vehicle is delivering acceptable ride quality. You will be able to visually see the impact of too much rebound. I can guarantee that any FCM Elite setup since 2014 would ride better than any Ohlins DFV, and out-grip them as well. Since we're on the subject of Alberto's FD RX-7, I know with confidence he'll trounce anyone using Ohlins, in any objective test. I'm happy to be part of that evaluation. I've displayed the fruits of my work on his dampers here, with the confidence that even if someone went and duplicated the rebound curve, you wouldn't get Ripple Reducer without the effort to size and drill those holes in the piston. And you wouldn't have KBO which is another essential ingredient in making our FCM Elite dampers the most technologically sophisticated and street-or-track-capable monotubes in the world.